As we move closer to a working prototype of our wearable triage monitoring system, we’ve reached one of the most hands-on and critical phases of development: circuit assembly. While simulations and digital design helped us plan the architecture, it’s in this stage — the physical construction — where theory meets reality.

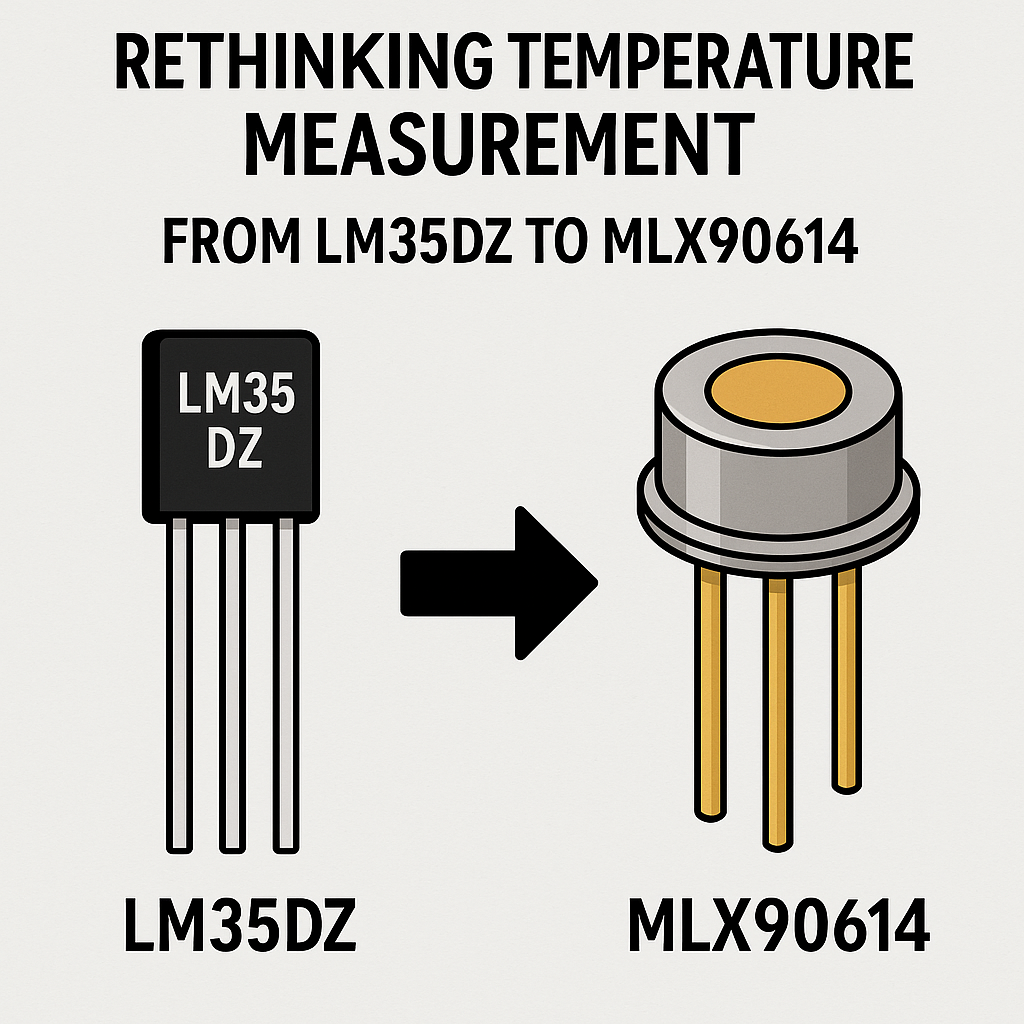

Issues with the LM35DZ

Inconsistent Skin Contact

Since the LM35DZ requires physical contact with the skin, any minor movement of the wearable resulted in inconsistent pressure or placement, which significantly affected the temperature readings.

Surface vs. Core Temperature

The sensor measures surface temperature, which is naturally lower than core body temperature and highly sensitive to ambient conditions. This made it difficult to extract meaningful health insights without applying compensation algorithms that added unnecessary complexity at this stage.

Noise and Calibration Challenges

The analog nature of the LM35DZ meant that small electrical fluctuations could introduce noise. Additional filtering and calibration steps were needed to stabilize the data.

We chose this sensor for its low-cost temperature measurement capabilities, but needed to ensure its performance met the requirements for our intended application. However, the tests yielded unsatisfactory results due to a lack of measurement precision, which led us to explore alternative options.

Integration and Next Steps

We're currently integrating the MLX90614 into our wearable prototype, connected to the ESP32-C3 via I2C for real-time processing. Initial tests show far greater consistency and usability than the LM35DZ, especially when used in mobile or semi-supervised environments like emergency units.

Additionally, the non-contact nature of the MLX90614 opens the door for multi-patient use cases, where triage wristbands could be temporarily applied or positioned for readings without skin contact, improving hygiene and usability in high-flow emergency rooms.

Technologies Used

After reviewing alternatives — and upon further discussion between the team members and considering real-world constraints — we decided to switch to the MLX90614, a contactless infrared temperature sensor module. This sensor brings multiple advantages that align more closely with our project's goals.

Why MLX90614?

- Non-contact measurement makes it more comfortable for the user.

- Digital accuracy using a built-in 17-bit ADC and I2C communication ensures clean and reliable data with less need for analog filtering.

- More representative of core body temperature,as it measures emitted infrared energy.

- Compact and energy-efficient, suitable for wearable integration.

- Faster response time, allowing near-instantaneous readings with minimal motion impact.

Conclusion

The decision to shift from the LM35DZ to the MLX90614 wasn't just a technical upgrade — it was a practical, medical, and user-focused improvement. This transition reflects our core project philosophy: combining smart engineering with healthcare usability to create a system that genuinely improves emergency care workflows.